Dispensing in perfection – this is what dosmatix does.

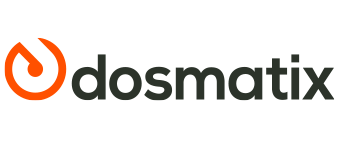

Development and support for our product portfolio is thus implemented by the building-block principle. Having intelligent systems means they can be integrated into existing production processes or used to replace manual tasks. Thanks to highly innovative technology and logical digitalisation, dosmatix dispensing systems achieve the highest level of process and resource efficiency.

Through the modular design of dosmatix dispensing system components, it has now become possible to focus uncompromisingly on customer desires and increase ease of maintenance and user-friendliness significantly.

dosmatix offers SMEs in the mechanical engineering and automation sectors a forward-looking platform with which they can integrate dosing processes flexibly, economically and resource-efficiently into their system environment.

dosmatix dispensing and metering solutions set new quality standards and offer previously unheard-of economic advantages: higher performance, optimal material consumption, simpler handling and future-proof integration – providing overall more cost-efficient material dispensing.

automotive

As part of automatic production processes, there are many quality-sensitive applications for which dosmatix offers systems with the highest process security: application of adhesives (e.g. in strips), sealing part connections, applying lubricants or potting and encapsulating high-value components.

e-mobility

Dispensing processes find outstandingly varied application in e-mobility. Just one example: robust adhesion between battery cells. Protecting the parts against temperature, vibration, dirt or penetrating damp are further uses for which dosmatix offers highly efficient and cost-saving solutions with its dosing modules.

industry

In industry, dispensing plays a key role. With parts getting ever smaller and compacter, providing ever-greater performance in a small space, precise dispensing of casting materials of every viscosity is the key to long life and reliability.

consumer electronics

Smartphones, the smart home, entertainment devices: the pressure to innovate is massive and the trend towards miniaturisation is forcing manufacturers to think up clever arrangements in small spaces. Precise material dispensing for the most varied purposes is a key technology here, ensuring perfect functionality.

electronics

The reliability of electronics determines the durability of complex products such as cars, aeroplanes and industrial facilities. Casting processes must be 100-percent exact.

Typical dispensing processes: Conformal coating, dam & fill, glob top, bonding, underfill und microdosing.

building technology

Front and centre here is protection against atmospheric influences such as temperature, damp and frost. The most varied processes are used to glue, cast and insulate. he materials used are immensely diverse: but dosmatix provides system solutions to fit the demands of every dispensing task.

aerospace

When dispensing cost-intensive high-tech materials, full exploitation must be achieved. dosmatix dispensing systems and metering systems are outstandingly efficient, fast and exact when gluing structures, sealing edges, filling hollows or sealing riveted and bolted components.

renewable energy

In the production processes for solar modules, generators in wind farms and batteries, casting applications, seals and insulation for electronics are decisive for quality.

medical technology

Quality, precision and reliability are the be-all and end-all here. Standards must be upheld and guaranteed over long periods. High-frequency cleaning processes stress materials, their glued joints and cast elements. dosmatix solutions offer process security for dispensing and potting in medical technology, for example, in the design of pacemakers or in a wide range of casting and gluing processes – including in clean rooms (ISO 5).

contact us

direct contact

sales(at)dosmatix.com

phone: +49 8783 9667 530