dispensing

new

defined.

dosmatix products have a modular design based on the building block principle. This opens up completely new potential for industrial users in terms of efficiency, cost savings and the ability to integrate their individual dispensing processes. Thanks to the uncompromising new design of dosmatix solutions, requirements for simpler maintenance, more user-friendly control and more economical use of expensive materials as well as consistently perfect dispensing results can be optimally met – whether for sealing, bonding, insulating, potting, sealing or thermal management. Benefit now from the innovative dispensing technology solutions from dosmatix.

our products – at a glance

dispenser

- piston dispenser dos piston

Material potting from 0.1 bis 106 ml. - progressive cavity dispenser dos screw

Spot dispensing from 15 μl and continuous bead application.

material preparation

- material preparation dos prep light

For abrasive and non-abrasive materials up to 70,000 mPa•s. - material preparation dos prep

For abrasive and non-abrasive materials up to 70,000 mPa•s.

- material preparation dos feed C

For abrasive and non-abrasive materials in cartridges from 70,000 mPa•s. - material preparation dos feed H

For abrasive and non-abrasive materials in hobbocks from 70,000 mPa•s.

kinematics

- stand dos workstation

stand solution for small series and prototypes. - integration dos in-line

Dispensing movement in 3 degrees of freedom. - stand-alone dos cell

Dispensing movement in 3 degrees of freedom with protection cell. - vacuum chamber dos vac

Vacuum chamber with integrated axis system for positioning components in 3 degrees of freedom.

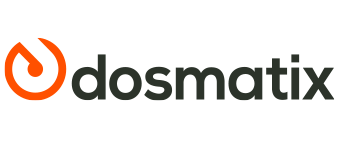

total systems at a glance

manual workstations

(Starter) solution

Cost-effective and space-saving alternative for manual dispensing applications.

Integration

module

Individually combinable

Individual products can be combined or integrated into production lines.

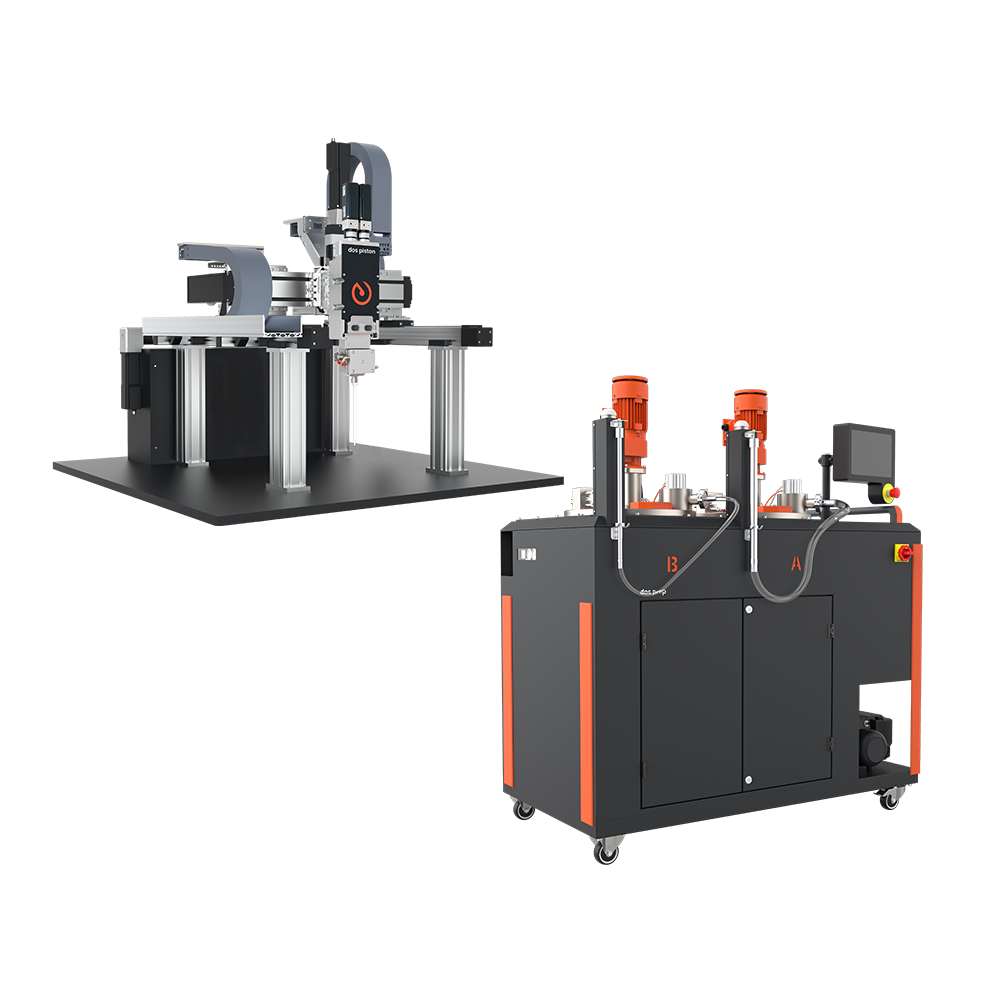

Standalone

Potting under atmosphere

Automated dispensing systems as standalone systems offer the ideal solution for series products.

Standalone

Potting under

vacuum

Depending on the application, potting under vacuum is required for challenging potting.

dispenser

Varied potting requirements, including diverse dispensing quantities and cycle times, set the specific technical requirements of the dispenser that is to be used. dosmatix dispensers offer ideal, tailor-made solutions for the precise potting of the most varied materials, making an important contribution to uncompromising quality and excellence in the end product.

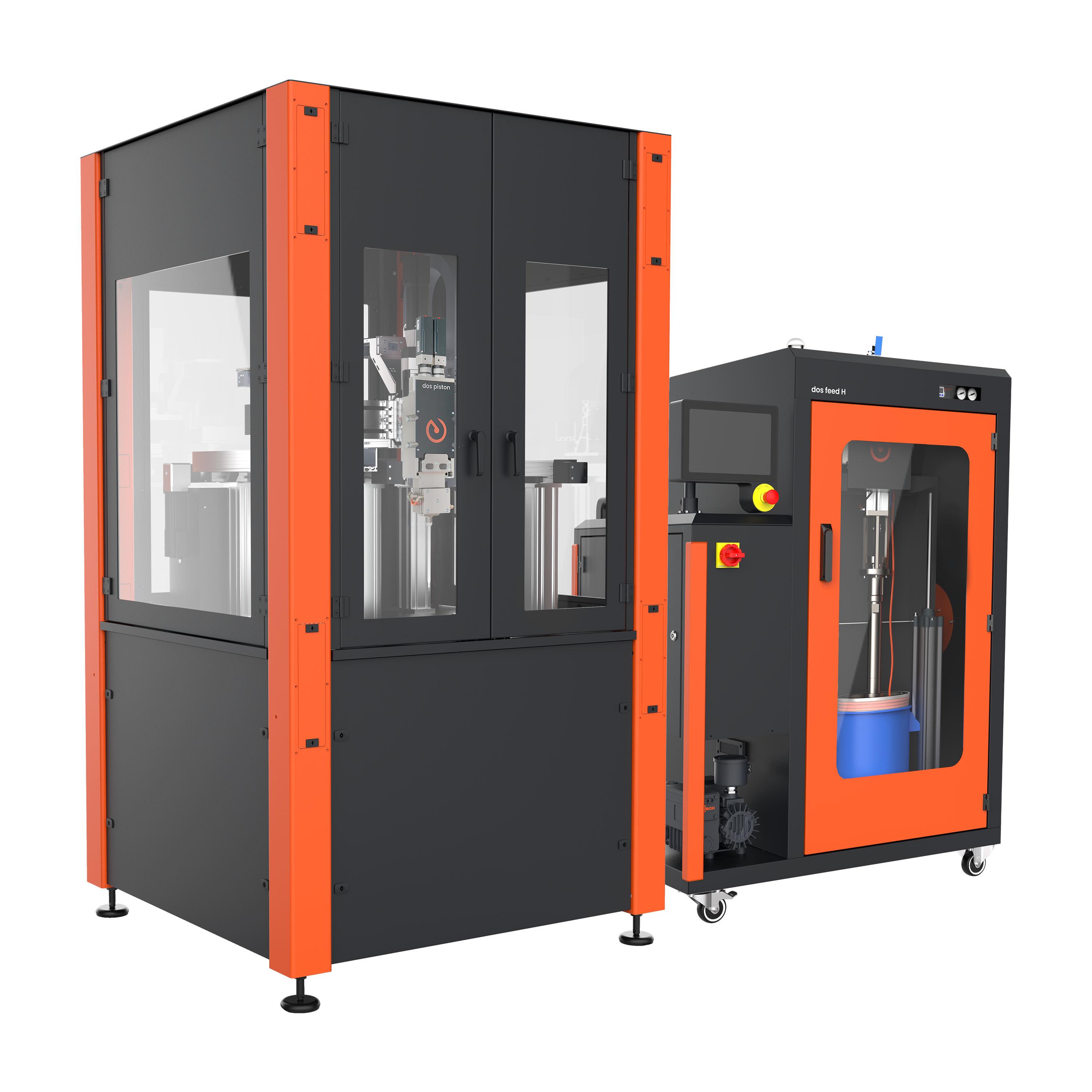

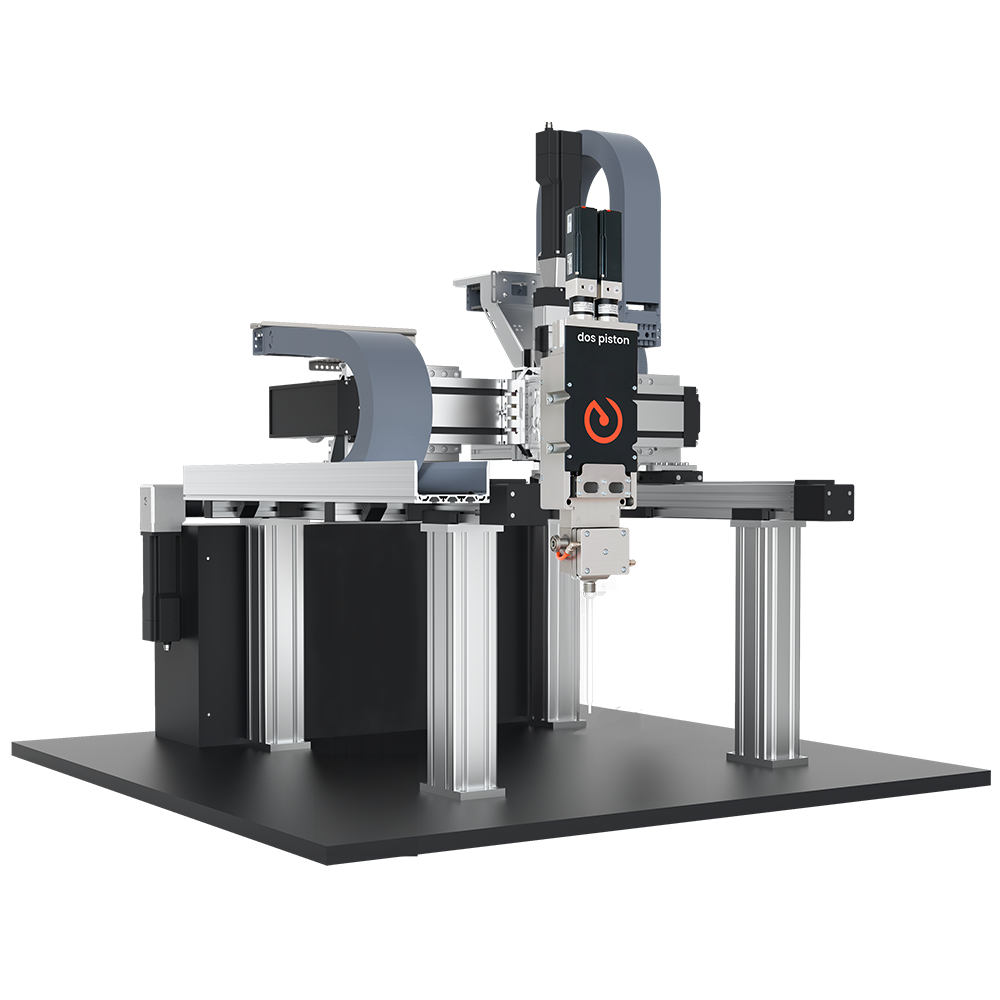

piston

dispenser

dos piston

Material potting from 0.1 to 106 ml for abrasive and non-abrasive materials.

Variants: M, L, M-A, L-A

progressive

cavity dispenser

dos screw

Spot dispensing from 15 µl and continuous bead application at a speed of up to 600 ml/min.

Variants: 1C and 2C

material preparation

Potting materials demonstrate a wide range of properties. Reliable dispensing thus requires optimal material preparation (e.g. degassing or temperature control) and fault-free transport of the materials to the dispenser. The type of material influences what type of material preparation is right for the application in question.

material preparation

dos prep light

Preparation and feeding with a fill volume of 0.5 or 3 liters.

Variants: 1C and 2C

material preparation

dos prep

Preparation and feeding of abrasive and non-abrasive materials up to viscosity of 70,000 mPa·s.

Variants: 1C and 2C

material preparation

dos feed C

Transport of abrasive and non-abrasive materials in cartridges from a viscosity of 70,000 mPa•s.

Variants: 6 oz. and 20 oz.

material preparation

dos feed H

Transport of abrasive and non-abrasive materials in hobbocks from a viscosity of 70,000 mPa•s.

Variants: 1C and 2C

kinematics

Diverse production environments and varying requirements of the potting and the process mean dispensers can be integrated in a manual workplace or fully automated CNC kinematic solution. dosmatix offers flexible solutions and delivers tailor-made additional functions to ensure reliability and safety in your potting process.

integration

dos in-line

Axis system for moving the dispenser through 3 degrees of freedom.

Variants: S, M, L

stand-alone

dos cell

Axis system including protection cell for moving the dispenser through 3 degrees of freedom.

Variants: S, M, L

vacuum chamber

dos vac

Vacuum chamber with integrated axis system for positioning components in 3 degrees of freedom.

Variants: M, L