dos cell

axis system with protection cell

axis system with protection cell

axis system with protection cell

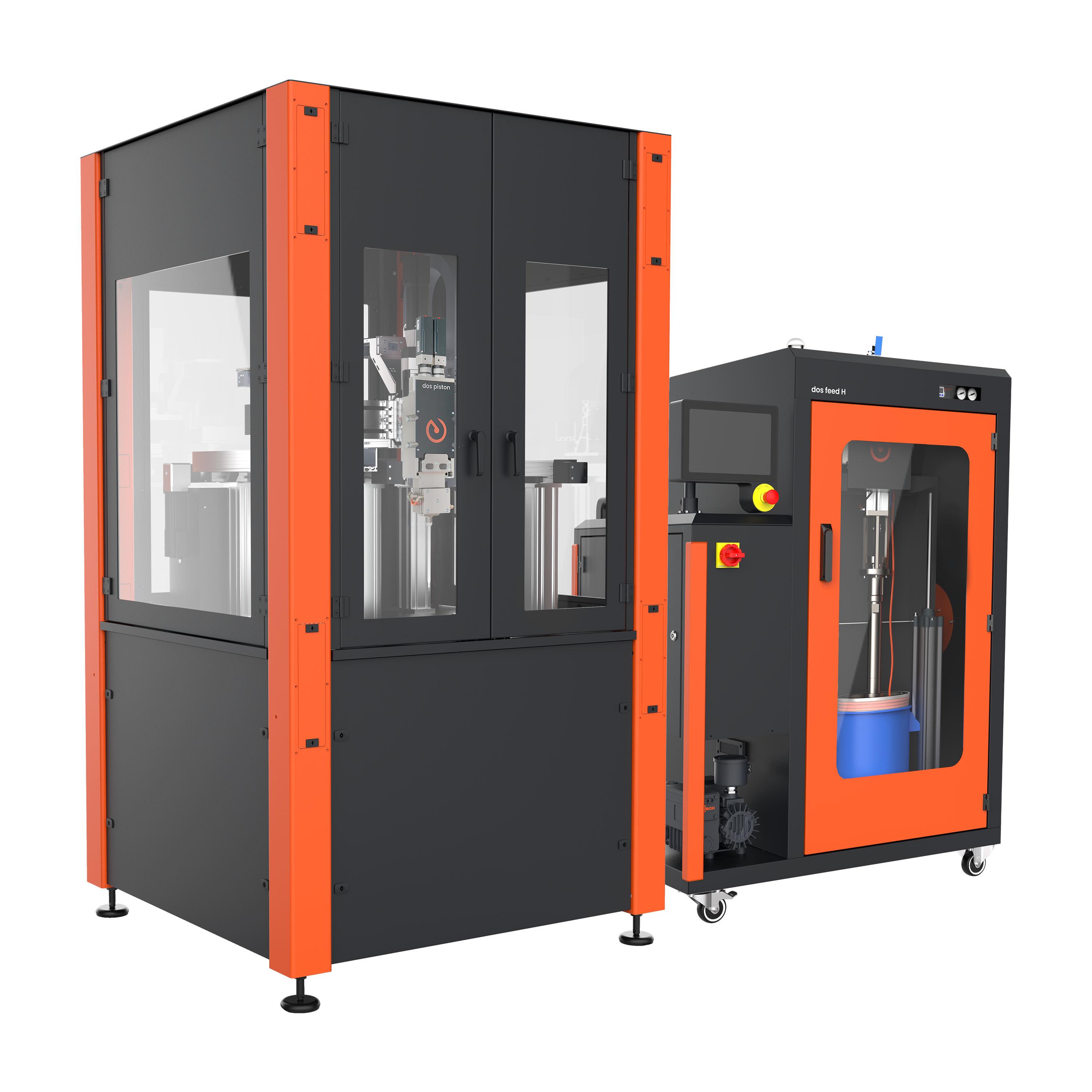

dos cell is a kinematic in form of a portal axis system, for moving a dispenser. Our dos cell is based on the identical foundation as our dos in-line, but is extended by a protective housing and further safety technology. It complies with all safety standards of an industrial series production. In combination with dosmatix dispensers like the dos piston, high traversing speeds and precise dispensing results are achieved in the shortest cycle times.

The dos cell is available in 3 standard sizes and can be used for a wide range of dispensing applications. The dos cell follows the dosmatix philosophy of the modular system.

High dispensing performance for series production.

any questions about the product? contact us:

| Variant | dos cell S |

| Outside dimensions (lxwxh) | 1250 x 1250 x 2300 mm |

| Weight | ca. 800 kg |

| Travel area XYZ* | 500 x 455 x 300 mm |

| Max. traverse speed | 600 mm/s |

| Dispensing speed | 35-50 mm/s |

| Repeat accuracy | 0:05 mm |

| Max. Loading (component weight) | 25 kg |

| Compressed-air supply | Min. 6 bar |

| Voltage supply | 230 V (Single-phase alternating current) |

| Control system | Beckhoff Automation |

| Variant | dos cell M |

| Outside dimensions (lxwxh) | 1500 x 1500 x 2300 mm |

| Weight | ca. 930 kg |

| Max. traverse speed | 600 mm/s |

| Dispensing speed | 35-50 mm/s |

| Repeat accuracy | 0.05 mm |

| Max. Loading (component weight) | 25 kg |

| Compressed-air supply | Min. 6 bar |

| Voltage supply | 230 V (Single-phase alternating current) |

| Travel area XYZ* | 750 x 705 x 300 mm |

| Control system | Beckhoff Automation |

| Variant | dos cell L |

| Outside dimensions (lxwxh) | 1750 x 1750 x 2300 mm |

| Weight | ca. 1200 kg |

| Travel area XYZ* | 1000 x 955 x 300 mm |

| Max. traverse speed | 600 mm/s |

| Dispensing speed | 35-50 mm/s |

| Repeat accuracy | 0.05 mm |

| Max. Loading (component weight) | 25 kg |

| Compressed-air supply | Min. 6 bar |

| Voltage supply | 230 V (Single-phase alternating current) |

| Control system* | Beckhoff Automation |

*in combination with dos piston M dispenser and dos prep material preparation

| Variant | dos cell S | dos cell M | dos cell L |

| Outside dimensions (lxwxh) | 1250 x 1250 x 2300 mm | 1500 x 1500 x 2300 mm | 1750 x 1750 x 2300 mm |

| Weight | ca. 800 kg | ca. 930 kg | ca. 1200 kg |

| Travel area XYZ* | 500 x 455 x 300 mm | 750 x 705 x 300 mm | 1000 x 955 x 300 mm |

| Max. traverse speed | 600 mm/s | 600 mm/s | 600 mm/s |

| Dispensing speed | 35-50 mm/s | 35-50 mm/s | 35-50 mm/s |

| Repeat accuracy | 0.05 mm | 0.05 mm | 0.05 mm |

| Max. Loading | 25 kg | 25 kg | 25 kg |

| Compressed-air supply | Min. 6 bar | Min. 6 bar | Min. 6 bar |

| Voltage supply | 230 V (Single-phase alternating current) | 230 V (Single-phase alternating current) | 230 V (Single-phase alternating current) |

| Control system | Beckhoff Automation | Beckhoff Automation | Beckhoff Automation |

*in combination with dos piston M dispenser and dos prep material preparation

dos piston

dos feed H

dos cell

dos in-line