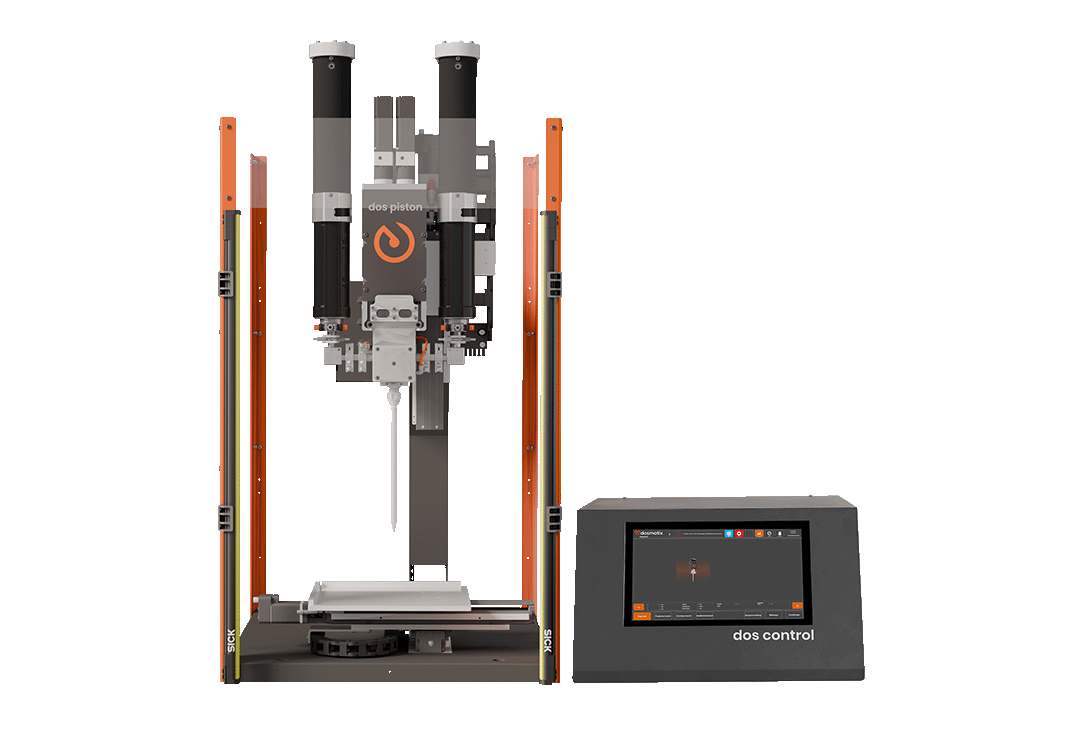

dos cell light

dispensing robot | bench-top robot

dispensing robot | bench-top robot

dispensing robot | bench-top robot

cartesian dispensing robot in compact format.

The dos cell light from dosmatix is a compact, CNC path-controlled 3-axis dispensing robot for precise applications with maximum repeat accuracy. The bench-top robot requires only a small footprint and offers a powerful complete solution for automated dispensing technology.

Equipped with robust linear axes, precise ball screws and powerful closed-loop motors, the system enables precise path control. An integrated safety housing and a high-quality controller from Beckhoff ensure safe, flexible and reliable process control.

The system is ideal for semi-automated production and precise dispensing applications – for example in electronics, medical technology, aerospace and other industrial sectors – for the application of potting materials or sealing beads.

Compact, easy to integrate, powerful

any questions about the product? contact us:

“Safety-first” – a safety

enclosure is included

Robust linear axes,

CNC path controlled

Recirculating ball screws

Beckhoff control system

"Safety first" - a safety enclosure is included

The safety enclosure ensures safe operation according to EU 2023/1230.

Robust linear axes, CNC path controlled

The robust linear axis enable precise movements and maximum repeat accuracy in the process – with high load-bearing capacity.

Recirculating ball screws

Precise ball screws and powerful closed-loop monitors ensure exact path control of the system.

Beckhoff control system

The industry-compatible control via Beckhoff Automation with user-friendly user interface enables centralized dispensing control via dos control.

► Central control: Efficient dispensing control for manual workstations and integration systems

► Intuitive operation: User-friendly user interface for simple control, monitoring and recipe management

► Industrially robust system: Based on the Beckhoff automation system – safe, reliable and compatible

► Flexible & customizable: Modular options such as different display sizes, cable lengths, swivel arm solutions and more…

| Variant | dos cell light |

| Dimensions (lxwxh) | 660 x 850 x 1175 mm |

| Weight incl. dispensing equipment | ca. 100 kg |

| Travel range XYZ | 300 x 300 x 300 mm |

| Repeat accuracy | + – 0,01 mm |

| Precise ball screw | 5 mm/rotation |

| Travel speed* | 80 mm/s |

| Max. Loading | Tool load capacity – 12 kg Workpiece load capacity – 5 kg |

| Compressed-air supply | Constant 6 Bar, class 5 DIN ISO 8573-1 |

| Power supply | 230V AC (L-N-PE) / 16A |

| Control system | Beckhoff Automation: Compact Industrial PC TwinCAT operating system – 3 EtherCAT TwinSAFE, UPS 1sec |

| Control panel | 12 inch color display |

| CNC: Mounting Control | 3-axis CNC mounting, closed-loop motors |

*Other configurations available on request

| Variant | dos cell light |

| Dimensions (lxwxh) | 660 x 850 x 1175 mm |

| Weight incl. dispensing equipment | ca. 100 kg |

| Travel range XYZ | 300 x 300 x 300 mm |

| Repeat accuracy | + – 0,01 mm |

| Precise ball screw | 5 mm/rotation |

| Travel speed* | 80 mm/s |

| Max. Loading | Tool load capacity – 12 kg Workpiece load capacity – 5 kg |

| Compressed-air supply | Constant 6 Bar, class 5 DIN ISO 8573-1 |

| Power supply | 230V AC (L-N-PE) / 16A |

| Control system | Beckhoff Automation: Compact Industrial PC TwinCAT operating system – 3 EtherCAT TwinSAFE, UPS 1sec |

| Control panel | 12 inch color display |

| CNC: Mounting Control | 3-axis CNC mounting, closed-loop motors |

*Other configurations available on request