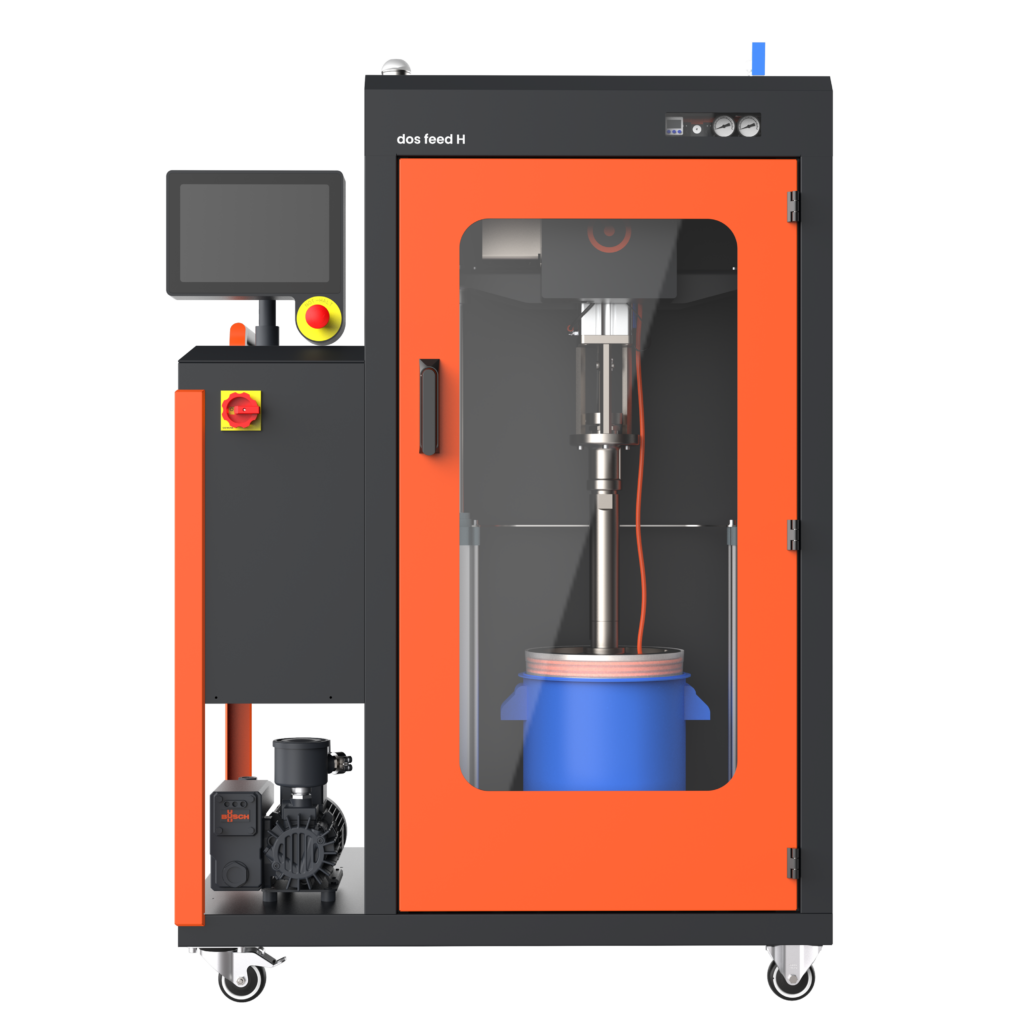

dos feed H

material feeding

material feeding

material feeding

dos feed H reliably feeds paste-like material at over 70,000 mPa·s into dispensing systems. Thanks to a modular pump concept, both abrasive and non-abrasive potting compounds can be transported.

The dos feed H designed by dosmatix enables bubble-free docking thanks to an innovative vacuum plate with FusionMesh technology. This ensures efficient feeding without material loss and is completed by an intelligent sensor system for system monitoring.

Efficient, economical and intelligent.

any questions about the product? contact us:

Modular pump concept

Innovative vacuum follower plate

Precise vacuum technology

Robust sensors and intelligent software

Modular pump concept (1)

dos feed H can be equipped with different pumps.

Variants:

Both pumps transport continually and ensure maximum material transport.

Innovative vacuum follower plate (2)

The innovative single-use plate without double bottom reduces material waste and optimizes the use of resources. Thanks to FusionMesh filter technology, docking is automated and bubble-free. Manual ventilation using the ball valve and material losses due to venting are eliminated.

Precise vacuum technology (3)

The use of a vacuum between the follower plate and the material ensures a reliable docking process and stops air from reaching the dispenser.

Robust sensors and intelligent software (4)

The integrated self-calibration automatically adjusts the pump speed, the delivery volume and the material pressure. Deviations are detected and adjusted in real time, increasing process stability.

| Pump type | Scoop piston pump |

| Hobbock size (nominal volume) | e.g. 22 litres (standard hobbock) |

| Feed volume | 27 ml/stroke |

| Electrical supply | 230V AC (L-N-PE) / 16A |

| Pneumatic supply | Constant 6 bar, class 5 DIN ISO 8573-1 |

| Dimensions (lxwxh) | 1C: 700 x 600 x 1802 mm 2C: 1400 x 600 x 1808 mm |

| Weight | 1C: ca. 155 kg 2C: ca. 300 kg |

| Control system | Beckhoff Automation |

| Pump type | Progressive cavity pump |

| Hobbock size (nominal volume) | e.g. 22 litres (standard hobbock) |

| Feed volume | 24 ml/rotation |

| Electrical supply | 230V AC (L-N-PE) / 16A |

| Pneumatic supply | Constant 6 bar, class 5 DIN ISO 8573-1 |

| Dimensions (lxwxh) | 1C: 700 x 600 x 1802 mm 2C: 1400 x 600 x 1808 mm |

| Weight | 1C: ca. 160 kg 2C: ca. 320 kg |

| Control system | Beckhoff Automation |

The original container (hobbock) is inserted into the barrel press.

The pump moves into the hobbock and docks onto the material.

Continuous material feed from the hobbock.

The potting material is transferred to the metering unit.

(Starter) solution

Cost-effective and space-saving alternative for manual dispensing applications.

Individually combinable

Individual products can be combined or integrated into production lines.

Potting under atmosphere

Automated dispensing systems as standalone systems offer the ideal solution for series products.