dos vac

vacuum dispensing system

vacuum dispensing system

vacuum dispensing system

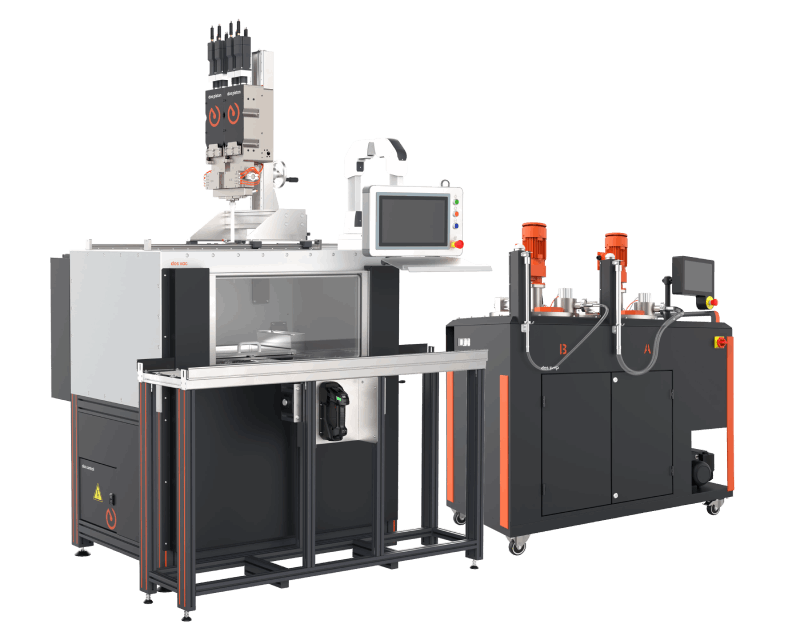

Vacuum dispensing is used to encapsulate particularly sensitive components from industries such as electronics, the automotive industry and medical technology without air pockets. The use of vacuum ensures an even distribution of the potting compound without cavities, even with tight geometries in the component. This leads to maximum functionality and reliability of the end products.

The dos vac vacuum chamber from dosmatix offers maximum precision and high-quality dispensing results. Thanks to its ease of operation and fast ventilation, efficient process times are also made possible.

Precise, efficient and with maximum functionality.

any questions about the product? contact us:

Service slide

Two-handed operation

Workpiece holder query

Vacuum door

Optional: Noise protection cover

Service slide (1)

An integrated service slide on the dos vac enables the user to carry out optimum maintenance and cleaning work on the dos piston thanks to its easy accessibility.

Two-handed operation (2)

The 2-hand control of the vacuum door ensures maximum user safety when closing the vacuum door and therefore contributes significantly to work safety.

Automatic workpiece holder query (3)

A sensor prevents operating errors and contamination due to incorrect dosing by automatically detecting a missing workpiece holder.

Vacuum door (4)

A generous, transparent door and additional windows provide the operator with an excellent view inside the chamber and improve user-friendliness.

Optional: Noise protection cover for vacuum pump (5)

A noise protection cover for the vacuum pump significantly reduces the noise level and ensures greater comfort and optimization of the workplace thanks to the effective noise protection.

▶ Automatic air regulation: A temperature sensor integrated in the sound enclosure regulates the fan speed to protect the vacuum pump from overheating by raising the fans as required.

▶ Connection to exhaust air system: The sound enclosure enables the connection of an external extraction system so that the exhaust air from the vacuum pump does not enter the production environment.

| Variant | dos vac M |

| Outside dimensions (lxwxh) | 1430 x 1450 x 2330 mm |

| Outside dimensions chamber (lxwxh) | 1140 x 790 x 565 mm |

| Weight (excl. vacuum pump) | ca. 700 kg |

| Potting area XY* | 400 x 300 mm |

| Travel area XYZ | 500 x 320 x 200 mm |

| Max. Component height without heating | 230 mm |

| Max. Travel speed XYZ | X,Y: 160 mm/s; Z: 50 mm/s |

| Movement kinematics Load suspension | max. 50 kg |

| Function | Vacuum potting up to 3 mbar |

| Compressed-air supply | Constant 6 bar, class 5 DIN ISO 8573-1 |

| Electrical supply | 400V AC (3L-N-PE) / 32 A |

| Control system | Beckhoff Automation |

* customization possible on request

| Variant | dos vac L |

| Outside dimensions (lxwxh) | 1585 x 1600 x 2480 mm |

| Outside dimensions chamber (lxwxh) | 1300 x 870 x 685 mm |

| Weight (excl. vacuum pump) | ca. 830 kg |

| Potting area XY* | 500 x 350 mm |

| Travel area XYZ | 600 x 370 x 300 mm |

| Max. Component height without heating | 350 mm |

| Max. Travel speed XYZ | X,Y: 160 mm/s; Z: 50 mm/s |

| Movement kinematics Load suspension | max. 50 kg |

| Function | Vacuum potting up to 3 mbar |

| Compressed-air supply | Constant 6 bar, class 5 DIN ISO 8573-1 |

| Electrical supply | 400V AC (3L-N-PE) / 32 A |

| Control system | Beckhoff Automation |

* customization possible on request

| Variant | dos vac M | dos vac L |

| Outside dimensions (lxwxh) | 1430 x 1450 x 2330 mm | 1585 x 1600 x 2480 mm |

| Outside dimensions chamber (lxwxh) | 1140 x 790 x 565 mm | 1300 x 870 x 685 mm |

| Weight (excl. vacuum pump) | ca. 700 kg | ca. 830 kg |

| Potting area XY* | 400 x 300 mm | 500 x 350 mm |

| Travel area XYZ | 500 x 320 x 200 mm | 600 x 370 x 300 mm |

| Max. Component height without heating | 230 mm | 350 mm |

| Max. Travel speed XYZ | X,Y: 160 mm/s; Z: 50 mm/s | X,Y: 160 mm/s; Z: 50 mm/s |

| Movement kinematics Load suspension | max. 50 kg | max. 50 kg |

| Function | Vacuum potting up to 3 mbar | Vacuum potting up to 3 mbar |

| Compressed-air supply | Constant 6 bar, class 5 DIN ISO 8573-1 | Constant 6 bar, class 5 DIN ISO 8573-1 |

| Electrical supply | 400V AC (3L-N-PE) / 32 A | 400V AC (3L-N-PE) / 32 A |

| Control system | Beckhoff Automation | Beckhoff Automation |

* customization possible on request

dos piston L – A

dos prep

dos vac