stand-alone

potting under atmosphere

potting under atmosphere

potting under atmosphere

automated dispensing under atmosphere.

Automated dispensing systems offer numerous advantages for the series production of components. They ensure precise and repeatable dispensing of a wide range of materials. This makes a decisive contribution to increasing the durability, quality and reliability of the manufactured components.

Compared to manual workstations, standalone dispensing systems offer enormous potential for increasing efficiency and reducing costs. With accelerated dispensing processes, increased production capacity and consistent dispensing patterns, they not only ensure the quality but also the functionality of electronic components – an indispensable factor for the success of modern production chains.

This is why a standalone system is the right solution

▶ Flexible system configuration based on specific dispensing requirements

▶ High cycle times and travel speeds thanks to automation

▶ Excellent potting quality for reliable and long-lasting results

▶ Complete solution from a single source

sealing, bonding, potting, sealing, insulating, thermal management

questions about the product? contact us:

Dispenser (1)

Material-

preparation (2)

Kinematic (3)

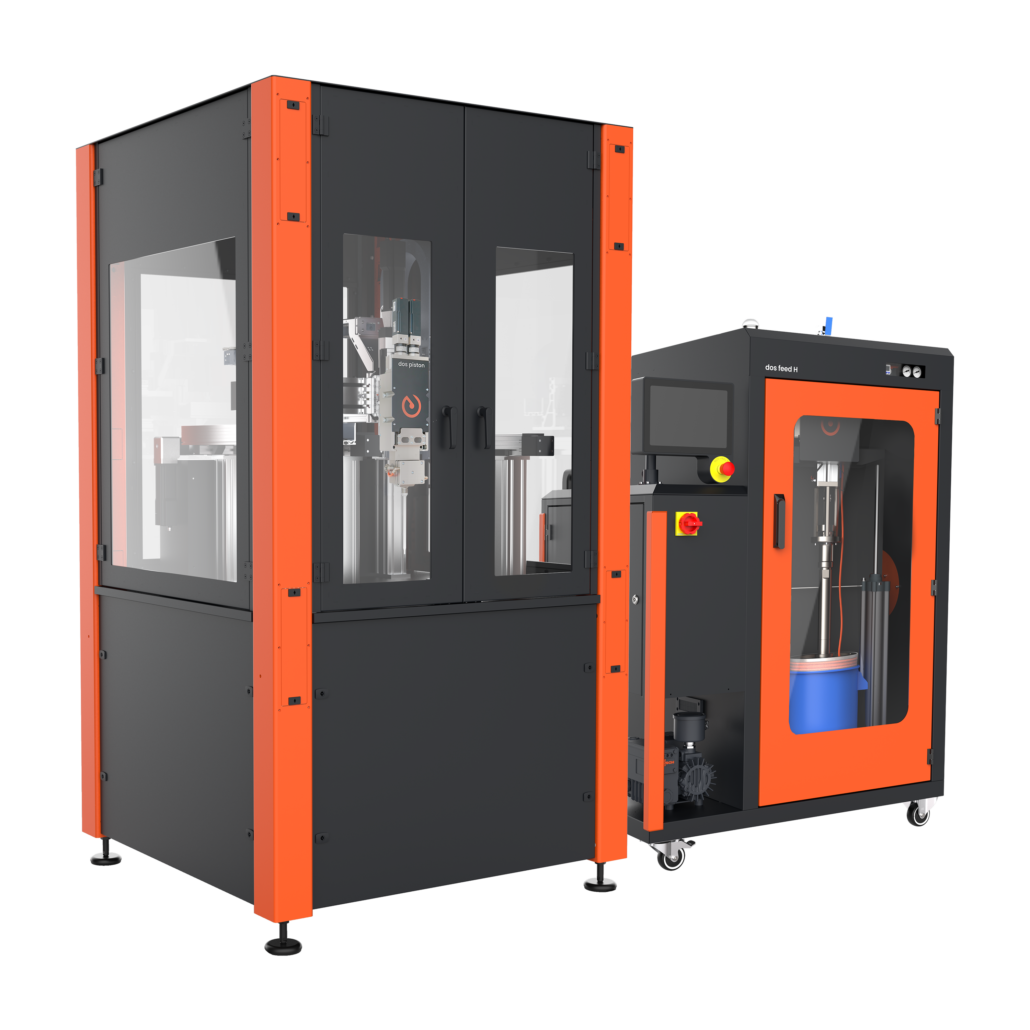

The all-in-one system solution ensures maximum integration and compatibility. We combine elements from the following product categories:

Dispenser (1)

Depending on the application, the standalone system can be equipped with a piston dispenser dos piston or an progressive cavity dispenser dos screw.

Material preparation (2)

The material preparation and feeding depends on the respective material and application. The following options are available: dos prep light, dos prep, dos feed C and dos feed H.

Kinematics (3)

The modular axis system with protection cell dos cell offers the latest safety standards in the field of atmospheric processes for high-performance dispensing.

Axis system with protection cell

Movement in 3 degrees of freedom

For abrasive and non-abrasive materials

Piston dispenser

Material potting from

0.1 to 106 ml

For abrasive and non-abrasive materials

Progressive cavity dispenser

Spot and endless

dispensing from 15 μl

For abrasive and non-abrasive

materials

Filling volume 0.5 and 3 liters

Material viscosity up to 70,000 mPa·s

For abrasive and non-abrasive materials

Filling volume per tank up to 60 liters

Material viscosity up to 70,000 mPa·s

For abrasive and non-abrasive

materials

Feeding from cartridges

Material viscosity from 70,000 mPa·s

For abrasive and non-abrasive

materials

Feeding from material hobbocks

Material viscosity from 70,000 mPa·s

For abrasive and non-abrasive

materials